Why Cahokia Went Down

My good friend Jeff Mann, the true Yard Ramp Guy, has asked me to revisit some of my original posts. This week in my From the Archives series: What really happened in America before Columbus?

Civilization & Its Discontent

One thing that happens to me—often—as I get older:

Learning that something I was taught in school was completely wrong. As you get older, it’ll also probably happen to you more and more, as well. We have more scientists and other researchers than ever before (in fact, 90% of all the scientists who have ever lived are alive today). So, human knowledge is advancing faster than ever.

Still: My Cup Remains Half Full

Plate tectonics was only discovered in the 60s. There are tons of people alive today who were taught nothing about it; they often learned those older, incorrect models of geology.

The most recent thing I learned that I'd been taught wrongly? America before Columbus.

When I was a kid, we were taught that America was a wild, largely empty place, with just a few Native Americans wandering around—like a small group of people alone in a stadium. As it turns out, though, that stadium was pretty packed.

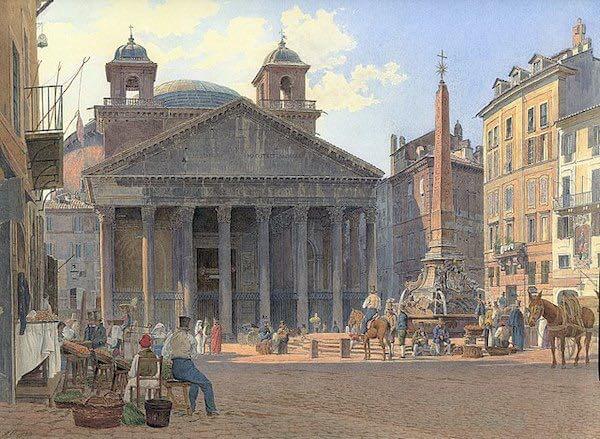

Charles C. Mann's excellent book 1491 is an exploration of recent historical and archaeological study into the pre-Columbian Americas. It turns out that massive, densely populated civilizations abounded in the Americas. The city of Cahokia was the size of London around the time Columbus showed up, and it was located near modern-day St. Louis.

The Aztec and Incan Empires both had populations comparable to many European nations at the time. Countless souls lived in massive cities in the Amazon rainforest. These last are the most mysterious of the lot, since it's such poor territory to preserve archaeological remnants. As we find more and more information on them, it becomes more and more apparent how impressive they must have been.

So, what happened to everyone? Well, in a single word: disease. Apocalyptic outbreaks of smallpox, syphilis, malaria, and more, all brought by Europeans, raced across the Americas, wiping out an absolutely terrifying 90% of the population of the Americas. The Native American populations Europeans encountered? In a very real sense, they were survivors of an apocalypse.

1491 is far from the most cheerful book I've ever read, but it's an incredibly informative one. It should be required reading for anyone interested in American history.

Yard Ramp Guy Blog: On Efficiency

This week, my friend The Yard Ramp Guy is on the trail of safer workplaces.

Click HERE to read his terrific insights.

We’ve heard of the Stone Age, the Bronze Age, and the Iron Age. And yet, we aren't commonly taught why those ages occurred in that order. Which is just too bad, since it's pretty darn interesting.

We’ve heard of the Stone Age, the Bronze Age, and the Iron Age. And yet, we aren't commonly taught why those ages occurred in that order. Which is just too bad, since it's pretty darn interesting.