From the Archives: Kiva Robots

My good friend Jeff Mann, the true Yard Ramp Guy, has asked me to revisit some of my original contributions. And so, my From the Archives series. This week: Kiva robots are a bit like forklifts.

Amazon is the biggest online retailer in existence. On some of their busier days, they've been known to receive more than 400 orders per second. Anyone who has ever worked in a warehouse can tell you that this is an absolutely astounding number. Even with warehouses all over, this would be a huge challenge for human workers. So, in 2012 Amazon purchased an army of robots for three quarters of a billion dollars.

The Kiva robots are like big, square Roomba robot vacuum cleaners, though they function more like forklifts. They're about 16 inches tall and weigh 320 pounds When a customer orders something on Amazon, a robot is dispatched with orders to retrieve the tall, thin square shelf that the item is on.

Kiva Robots: A Standing Army

The Kivas roll through the Amazon warehouses, carefully guided and controlled by a central computer to avoid collisions. They scoot under shelves, stopping when they reach the programmed location and spin in place to lift the shelf. Then they pilot the whole shelf to a station where a human employee grabs the customer's order. The order then travels through an array of other steps to get to the customer.

Amazon has more than 15,000 of these robots in their warehouses right now, processing a majority of the orders. Establishing a testing a system for a warehouse can take quite a while, sometimes months.

Amazon's engineers have to assure that the army of robots on the warehouse floor can move about without running into one another and toppling shelves over left and right, which is no easy task.

They also have to set the system up for prioritizing where to set shelves, in order to minimize retrieval times for the robots.

Surprisingly enough, the Kiva robots haven't resulted in job losses. Instead, the workers move from the picking-and-sorting jobs to train in other positions. In this scenario, when more robots are added, more work is created for the human workers.

Seemingly: everybody wins. Plus, as anyone who has ever worked in a warehouse can easily attest, picking is a job tailor-made for robots.

The Yard Ramp Guy Blog / A Yard Ramp Guy Primer

This week, my friend The Yard Ramp Guy steels us for some fascinating and promising changes in...er, steel itself.

Click HERE to breathe better air about it.

Archives: The Amazing Spider, Man

My good friend Jeff Mann, the true Yard Ramp Guy, has asked me to revisit some of my original contributions. And so, my From the Archives series. This week: spider silk!

Oh, What a Tangled Web We Weave

Another Busy Day at the Office?

If you're not a fan of spiders, you may want to skip this one. Otherwise, I just might’ve already snared you:

Spider silk is one of the most magnificent substances in nature, and there are a ton of different types of spider silk.

The silk can be used to capture prey. Along with their classic web-shaped design, spiders build webs in orbs, tangles, sheets, lace, and domes. One type of spider even lowers single-strand webs to go fishing.

Spiders tie up their prey in webs; a few species actually have venomous webs they use for this purpose. Other spiders produce extremely lightweight webs for “ballooning”—spiders blown along for dozens or even hundreds of miles by the wind, often in enormous swarms. (Yay, Australia!) Others use silk to lay trails to and from their web, and create alarm lines with it.

On top of that, spiders usually are capable of creating multiple types of silk—up to seven types in a single species.

Humans have studied and adapted countless different uses for spider silk. The spider-silk protein is comparable in tensile strength to high-grade alloy steel at one-sixth the density. We have stronger materials, like Kevlar, but none nearly so lightweight. (The strongest spider silk variety is more than ten times stronger than Kevlar.)

Spider silk is extremely stretchy and ductile, retaining its useful properties across a huge temperature range. The silk even makes for excellent bandages, due to its antiseptic qualities, and contains high amounts of vitamin K, which is useful in clotting blood.

Yes, the stuff that spiders spin is extremely useful. So, why don't we use it industrially? Because spider-farming doesn't work. Spiders eat each other. Instead, we've turned to genetic engineering. We've tried altering silkworms, E. Coli, goats (they produced it in their milk), tobacco plants, and potato plants to produce the protein.

We haven't mastered silk well enough to mass-produce, yet, but it'll happen eventually. (And then we'll get spider-web suspension bridges. Completely not creepy!)

The Yard Ramp Guy Blog / A Yard Ramp Guy Primer

This week, my friend The Yard Ramp Guy describes how his company rents, sells, and buys new and used yard ramps throughout the United States. It's quite detailed and fascinating.

Click HERE to read the impressive scope of his operation.

Archives: The Kessler Cascade

My good friend Jeff Mann, the true Yard Ramp Guy, has asked me to revisit some of my original contributions. And so, my From the Archives series. This week: proper waste disposal is important, even in space.

Or: In Space, No One Can Hear You Take Out the Trash

My family goes to a lot of movies. We're not film buffs, by any means. Usually, we're looking for snappy dialogue and explosions.

A couple years ago, we saw the film “Gravity.” For those who haven't seen it, a runaway debris cloud destroys satellites and space stations. Even though the science in that movie was pretty badly off, in a lot of ways, something like it does have the potential to occur.

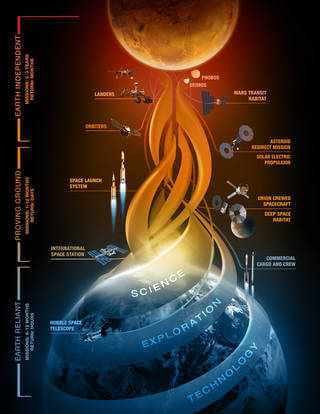

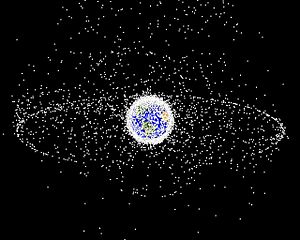

Kessler Syndrome is a hypothetical scenario dreamed up by a NASA scientist named Donald Kessler in the 70s. Essentially, it proposes that if enough objects are in low Earth orbit, collisions between them will eventually result in an enormous cascade of debris.

It's a pretty simple process: one piece of space junk slams into another, which sends debris scattering about.

Some of that debris hits another piece of space junk, creating another burst of debris, which slams into more space junk, and then maybe into a satellite.

Eventually, you have an enormous cloud of debris traveling through orbit. Each piece would be widely spaced, but even tiny bits can have insanely destructive power when moving that quickly. The cloud wouldn't take out every satellite, of course; it would stay in the same orbit, and many satellites would be in a higher or lower orbit.

A Kessler cascade could potentially make space travel impossible for millennia, completely blocking off that orbit. The debris wouldn't orbit forever. The drag from the miniscule amount of air at that altitude, along with a few other factors, would eventually clear the orbit again, though the process could take thousands of years.

Governments take the threat quite seriously. Satellites aren't allowed to launch unless they can be safely disposed at the end of their lifespans. The two most common techniques for doing so: dropping it back into the atmosphere or raising it up into a higher graveyard orbit.

People also have proposed gadgets for clearing the debris, including a device called a laser broom, which is precisely as cool as it sounds.

It all really just goes to show: proper waste disposal is important, no matter where you are.

The Yard Ramp Guy Blog / Eric Aguilera: Into The Mix

This week, my friend The Yard Ramp Guy welcomes Eric Aguilera to the team. He worked on the space shuttle. And he spells his last name just like Christina Aguilera does. So, I'm confident with this new addition to the fine team.

Click HERE to read all about Eric.

Archives: The VHS Loop

My good friend Jeff Mann, the true Yard Ramp Guy, has asked me to revisit some of my original contributions. And so: my From the Archives series. This week: ah, that VHS technology has me all holiday-nostalgic.

The End of the VHS Loop

The End of the VHS Loop

Maggie had me cleaning out the attic the other day, and I found a cardboard box filled with old VHS tapes. We hadn't used the VCR in something like a decade, but I managed to find it (in the garage, under five or six cans of paint) and hooked it up.

I went through some of our old home videos, and found that some worked perfectly fine and others didn't work at all. There didn't seem to be any real link between their age and how well they worked, either, so I decided to do some research.

There are lots of stories bouncing around the internet about how VHS tapes are supposed to stop working after ten years, or 15, or 20, but there doesn't seem to be any real consensus. People have written their anecdotes about all sorts of lifespans for the dumb things.

It turns out that there are a lot of reasons for the wildly different stories. First off, there was a lot of advertising done when DVDs came out—trying to convince people to switch from VHS to DVD, with the claim that VHS tapes wouldn't last very long.

And the conditions that cause the tapes to wear out vary wildly. VCR malfunction is the quickest cause, of course, but other factors include: rapid temperature swings, frequent use, low humidity, proximity to magnets and electronics, and storage conditions.

What makes it even more confusing is that many of the factors aren't even consistent. Infrequent usage can sometimes cause the tapes to fail, and frequent use can do the same thing.

What makes it even more confusing is that many of the factors aren't even consistent. Infrequent usage can sometimes cause the tapes to fail, and frequent use can do the same thing.

The last movie released on VHS was “A History of Violence,” in 2006. I doubt that a copy of this will be the last movie ever watched in the format, of course: by that time DVDs had pretty much taken over the whole scene, leaving very little of a VHS market remaining. The “last view” honor will most likely go to someone's home movie, and probably within the next 50 years.

The Yard Ramp Guy Blog: Your Holiday Ramp Cheer

This week, my friend The Yard Ramp Guy dusts off the power of the pen, much mightier than the sword, and scribbles a great poem in tribute to the much, much mightier yard ramp.

Click HERE to get yourself well-versed.